Application: This equipment is applied in battery cell manufacturing and is a customized machine. Our design varies from customers’ requirements, the brief information is as follows:

Parameters:

Size: 11m × 3m × 3m

Capacity: ≥15 ppm

Yield: 99.8%

Application: This equipment is applied in battery cell manufacturing and is a customized machine. Our design varies from customers’ requirements, the brief information is as follows: Parameters: Size: 11m × 3m × 3mCapacity: ≥15 ppmYield: 99.8%

Application: This equipment is applied in battery cell manufacturing and is a customized machine. Our design varies from customers’ requirements, the brief information is as follows: Parameters: Size: 11m × 3m × 3mCapacity: ≥15 ppmYield: 99.8%

Dive into the world of enhanced battery safety and durability with our Cell Taping Line - a specialized assembly system meticulously crafted for the application of insulating tape on battery cells. This state-of-the-art machinery is designed to cater to the precise needs of battery cell insulation, ensuring that each cell is wrapped with an impeccable layer of protection. The Cell Taping Line is not just a machine; it's a testament to our commitment to quality, safety, and innovation in battery cell manufacturing.

Our Cell Taping Line is engineered to provide a seamless and efficient process for applying insulating tape on battery cells. This critical step enhances the safety and longevity of batteries, making it an indispensable part of the battery production process. The machine's design is a reflection of our understanding of the intricate requirements of various applications, where the reliability and performance of batteries are paramount.

The Cell Taping Line operates with a blend of precision and automation technology that ensures every battery cell receives a uniform and accurate application of protective tape. The machine's advanced automation system is programmed to apply layers of tape with a level of precision that eliminates human error, ensuring consistent quality across all battery cells.

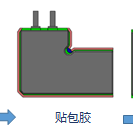

The process begins with the battery cells being fed into the machine, where they are held in place by a series of precisely controlled grips. The machine then guides the insulating tape around the cells with a high degree of accuracy, ensuring that the tape is applied smoothly and without overlap or gaps. The machine's advanced sensors monitor the application process in real-time, making minute adjustments as needed to maintain the highest level of quality.

The versatility of our Cell Taping Line makes it a valuable asset across a spectrum of industries. It is primarily used in the automotive sector, where the reliability of batteries in electric and hybrid vehicles is crucial. In the electronics industry, our machine ensures that batteries for devices ranging from smartphones to laptops are protected and durable. Additionally, the renewable energy sector, with its focus on sustainable and efficient energy storage, also benefits from the precision and consistency that our Cell Taping Line offers.

The technical workings of the Cell Taping Line are a testament to its sophisticated design and engineering. The machine integrates a series of sensors and control systems that work in harmony to apply taping materials under exact conditions. The sensors in the machine detect the position and shape of each battery cell, feeding this information to the control system. This data is then used to adjust the application of the tape to ensure a perfect fit every time.

The machine's control system is the brain of the operation, coordinating the movement of the tape and the battery cells to achieve a seamless application process. It also monitors the tension of the tape and the speed of application, making real-time adjustments to maintain the highest level of quality and consistency.

In addition to its technical prowess, the Cell Taping Line is designed with user-friendliness in mind. Its intuitive interface allows operators to input parameters and make adjustments with ease, reducing the need for extensive training. The machine's modular design also allows for easy maintenance and integration into existing production lines.

Application: This equipment is applied in battery cell manufacturing and is a customized machine. Our design varies from customers’ requirements, the brief information is as follows:

Parameters:

Size: 11m × 3m × 3m

Capacity: ≥15 ppm

Yield: 99.8%

A Cell Taping Line is an advanced automated production system designed to apply adhesive tapes to battery cells with precision and efficiency. This equipment is widely used in the battery manufacturing industry, particularly for lithium-ion batteries, where consistent taping is crucial for ensuring safety, performance, and durability. By integrating cutting-edge technology, the Cell Taping Line streamlines the taping process, making it an essential tool for manufacturers aiming to enhance production efficiency and product quality.

The machine is equipped with advanced sensors and control systems that ensure accurate tape placement and tension, minimizing errors and material waste. Its ability to handle various cell sizes and tape types makes it a versatile solution for diverse production needs.

The primary function of a Cell Taping Line is to apply adhesive tapes to battery cells in a precise and uniform manner. This process is critical for securing cell components, preventing short circuits, and improving thermal management. The machine's advanced sensors and control systems ensure accurate tape placement and tension, minimizing errors and material waste.

Key benefits of the Cell Taping Line include improved production speed, reduced labor costs, and enhanced product reliability. Its automated operation ensures consistent taping quality, reducing the risk of defects and improving overall battery performance. Additionally, the machine's flexibility allows it to handle various cell sizes and tape types, making it a versatile solution for diverse production needs.

The Cell Taping Line is primarily used in the battery manufacturing industry, particularly for lithium-ion batteries. These batteries are widely used in electric vehicles (EVs), consumer electronics, and energy storage systems. The machine is also applicable in other industries where precise taping is required, such as the production of capacitors and other electronic components.

In the EV industry, the Cell Taping Line plays a critical role in ensuring the safety and performance of battery packs. By providing consistent and reliable taping, it helps manufacturers meet stringent quality standards and regulatory requirements.

The Cell Taping Line is designed to meet high industrial standards. It typically supports cell sizes ranging from 18650 to 21700 and beyond, with a taping speed of up to 200 cells per minute. The machine is equipped with precision alignment systems, ensuring tape placement accuracy within ±0.2 mm. It also features adjustable tension control, allowing operators to fine-tune the taping process for different tape types and thicknesses.

The machine is built with durable materials and components, ensuring long-term reliability and minimal maintenance requirements. Its user-friendly interface allows operators to easily monitor and adjust settings, ensuring optimal performance.

The Cell Taping Line operates by feeding battery cells through a series of stations, where adhesive tapes are applied with precision. The process begins with cell alignment, followed by tape application and cutting. Advanced sensors and cameras ensure accurate tape placement, while automated systems adjust tension and alignment as needed.

Once the taping process is complete, the cells are inspected for quality and consistency. Any defective cells are automatically flagged and removed from the production line. The entire process is automated, ensuring high efficiency and minimal human intervention.

One of the standout advantages of the Cell Taping Line is its ability to deliver consistent and precise taping, significantly improving product quality and performance. Its automated operation reduces labor costs and minimizes the risk of human error, making it a reliable choice for high-volume production.

The machine's adaptability to various cell sizes and tape types makes it a cost-effective solution for diverse production needs. Additionally, its robust construction and low maintenance requirements contribute to long-term operational efficiency, reducing downtime and increasing productivity.

When operating a Cell Taping Line, it is essential to consider factors such as tape compatibility, cell size, and production speed. Regular maintenance, including cleaning the tape application heads and inspecting the alignment systems, is crucial to ensure optimal performance.

Operators should be adequately trained to handle the machine’s controls and troubleshoot common issues. Selecting the right tape materials and adjusting parameters based on specific production needs are key to achieving the best results. Proper planning and attention to these considerations will maximize the machine's performance and longevity.